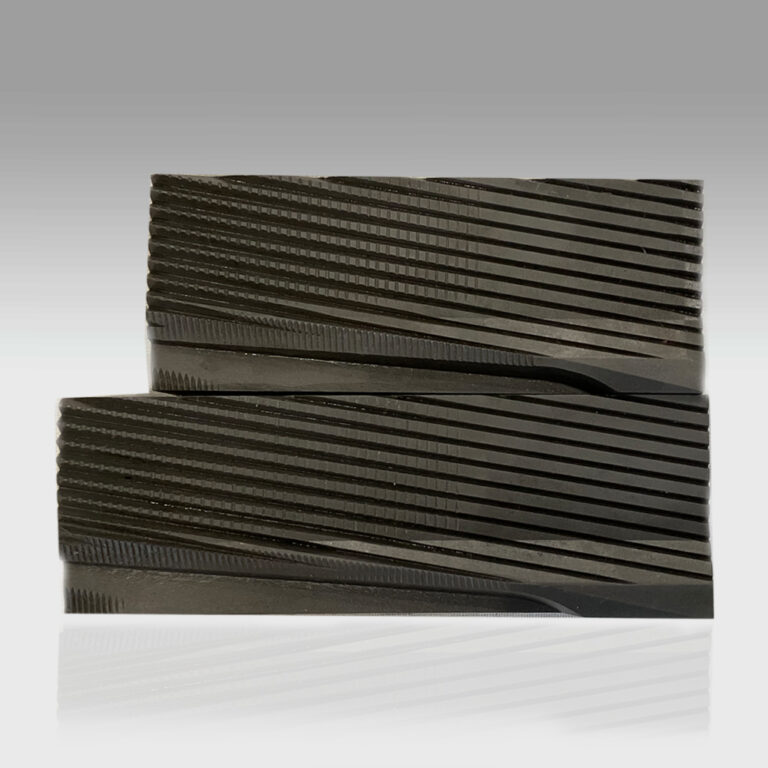

Thread rolling dies for customized screws serve a critical role in the realm of specialized fastener manufacturing. When it comes to screws that deviate from the standard dimensions and profiles, these precision-engineered tools are indispensable. Unlike conventional cutting methods, thread rolling employs a process that relies on pressure to mold the material into threads. This results in threads that exhibit superior strength and resilience, making them highly desirable in applications where durability and reliability are paramount.

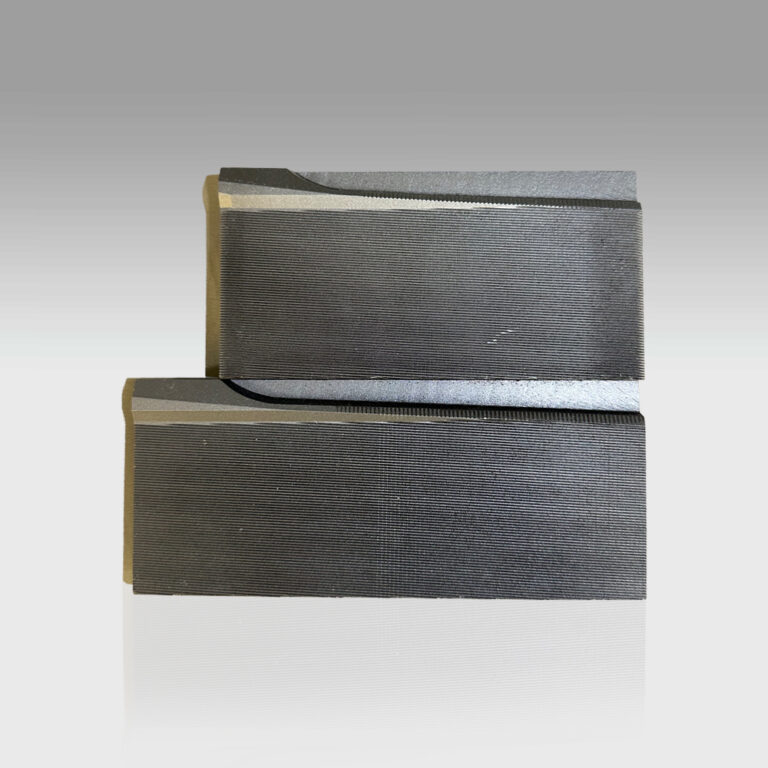

Crafting thread rolling dies tailored to customized screws is a task that demands a profound understanding of the unique specifications at play. This encompasses considerations such as pitch, diameter, thread form, and material composition. Seasoned professionals in this field utilize advanced machining techniques and select only the highest quality materials to fashion these dies. This ensures that they not only meet but often exceed the stringent standards set forth by industries.

The adaptability of thread rolling dies is a hallmark feature, allowing for the production of screws that are tailor-made for highly specialized applications. This can encompass a broad spectrum of industries and sectors, ranging from automotive to construction and electronics. In essence, these dies facilitate the creation of fasteners that are not only reliable but also optimized for the specific demands of their designated use cases.

Moreover, the benefits of thread rolling extend beyond the immediate advantages of enhanced strength and longevity. This method also tends to produce threads with smoother surfaces and more precise dimensions, reducing the likelihood of galling or other forms of thread damage during assembly. Additionally, thread rolling can be a more cost-effective process in the long run, as it minimizes material waste.

In conclusion, thread rolling dies for customized screws epitomize the marriage of precision engineering and manufacturing expertise. Their role in producing fasteners that deviate from conventional norms is indispensable, ensuring that industries have access to reliable and tailored solutions for their specific needs. Through a combination of advanced techniques, high-grade materials, and a deep understanding of unique specifications, these dies stand as a testament to the ingenuity and craftsmanship that underpins modern manufacturing processes.

Contact us for any query. We are happy to help you.

Features

- Advanced Metallurgy: Employing state-of-the-art metallurgical techniques, Customized Thread Rolling dies are engineered from high-grade tool steel alloys. This ensures superior wear resistance, toughness, and prolonged die life, even under demanding operational conditions.

- Micro-Precision Profiling: These dies undergo a rigorous regimen of quality testing and inspection, allowing for micro-precision profiling of thread patterns. This level of accuracy guarantees uniform and flawless thread formation, even in challenging materials, contributing to superior fastening performance.

- Thermal Treatment Expertise: Each die undergoes a specialized heat treatment process, meticulously controlled to achieve optimal hardness levels. This precision heat-treating imparts exceptional durability, ensuring sustained performance over an extended operational lifespan.

- Innovative Thread Geometry: The die's thread geometry is engineered with innovative flank angles and radius, allowing for efficient chip evacuation and reduced workpiece stress. This results in superior thread integrity and surface finish, even in high-strength or brittle materials.

- Customizable Configurations: These dies offer a range of customizable options, from specialized surface finishes for specific applications to tailored thread profiles. This adaptability ensures versatility, enabling the die to address diverse fastening requirements in various industrial sectors.