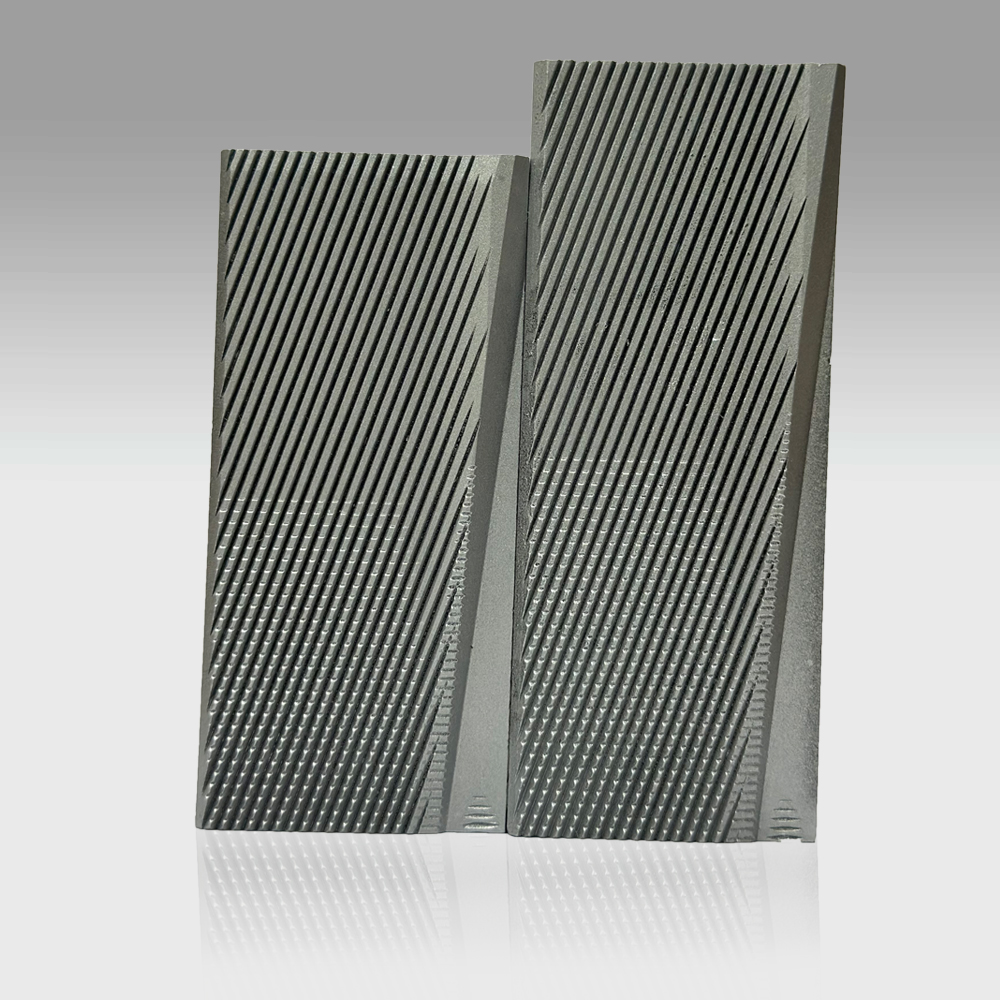

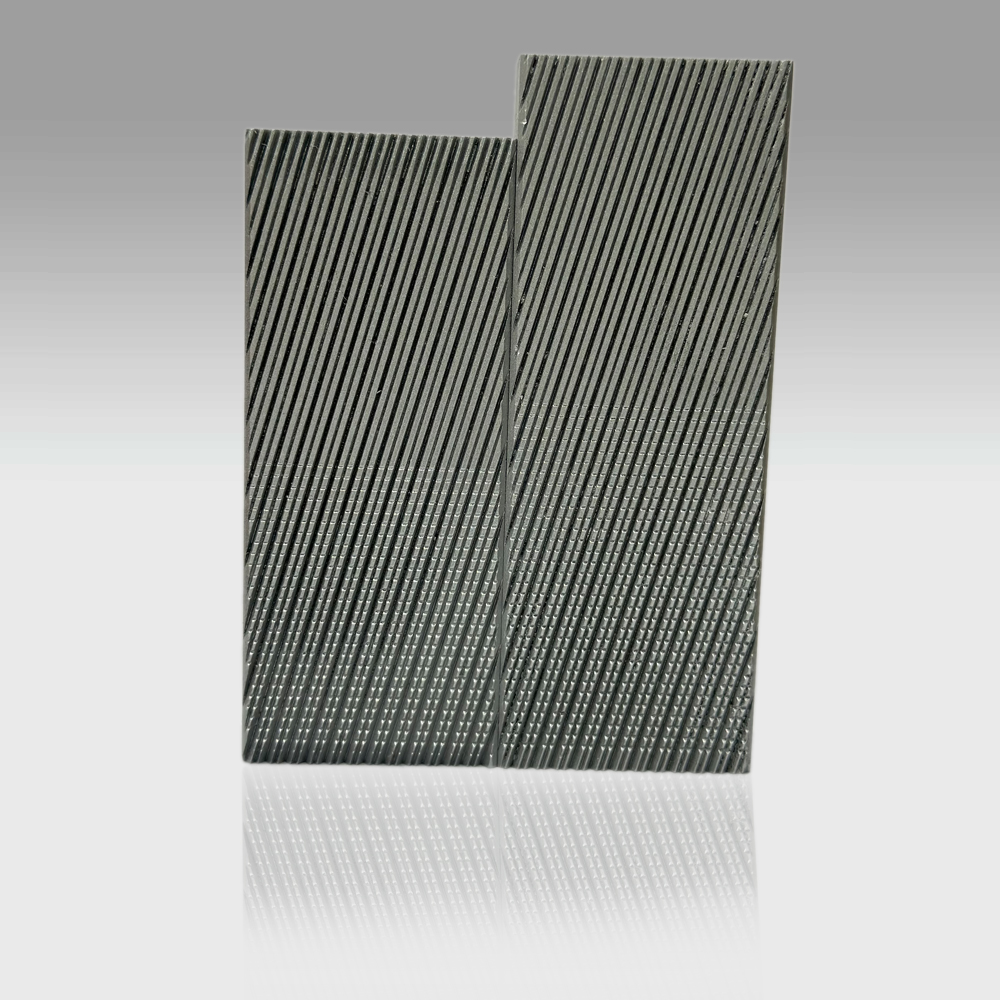

FLAT THREAD ROLLING DIES MANUFACTURER & SUPPLIER

Flat Thread Rolling Dies Manufacturer in India

Welcome to Accusize Carbide – Your Premier Destination for High-Quality Flat Thread Rolling Dies!

At Accusize Carbide, we take immense pride in being a leading Flat thread rolling dies manufacturer in India, specializing in all kinds of Flat Thread Rolling Dies. With a legacy of excellence spanning years, we have firmly established ourselves as a trusted name in the industry, known for our precision, durability, and innovation.

We provide thread rolling dies in milled and ground thread form. We make sure that the dies manufactured are highly durable, tempered and made with best quality steel. We export these dies all over the world. At Accusize Carbide, we make sure to manufacture the thread rolling dies in various thread forms like ANSI, DIN, JIS etc.

| Specification | Details |

|---|---|

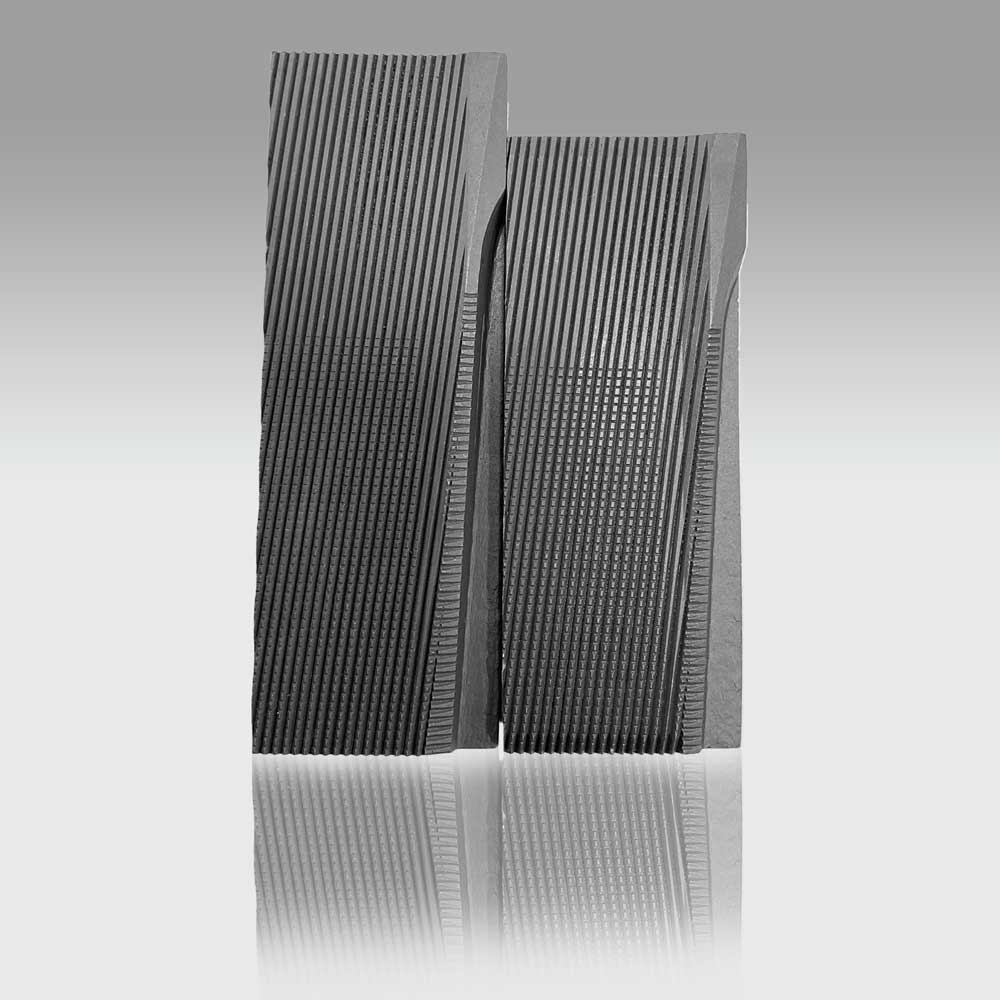

| Thread Form | Ground thread form and milled thread form |

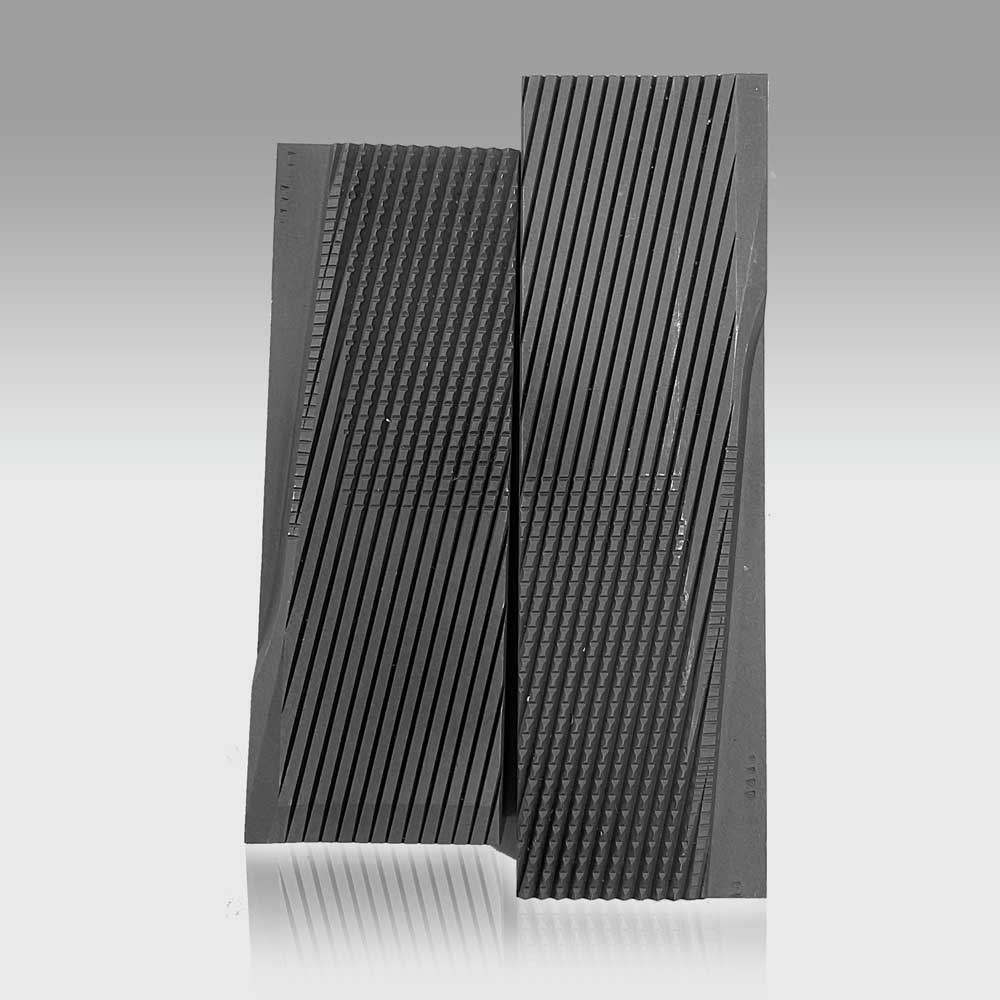

| Die Types | Single-face and duplex-face |

| Standards | Manufactured to JIS class standards |

| Material | High-grade steel, fully tempered, and hardened with precise grain structure |

| Production Process | Utilizes pusher blade mechanism for workpiece insertion and one-stroke thread formation |

| Hardness after Heat Treatment | 64-65HRC |

| Durability | Excellent heat treatment ensures long-lasting performance |

| Availability | Exported to various countries worldwide |

| Thread Forms | Available in ANSI, BS, DIN, and JIS thread forms |

| Production | Fully automated |

As a thread rolling dies manufacturer, we offer a comprehensive range of flat thread rolling dies, serving to variety of thread profiles, dimensions, and material requirements. Whether it’s standard thread sizes or custom specifications, our experienced team works closely with clients to deliver customized solutions that meet their exact needs.

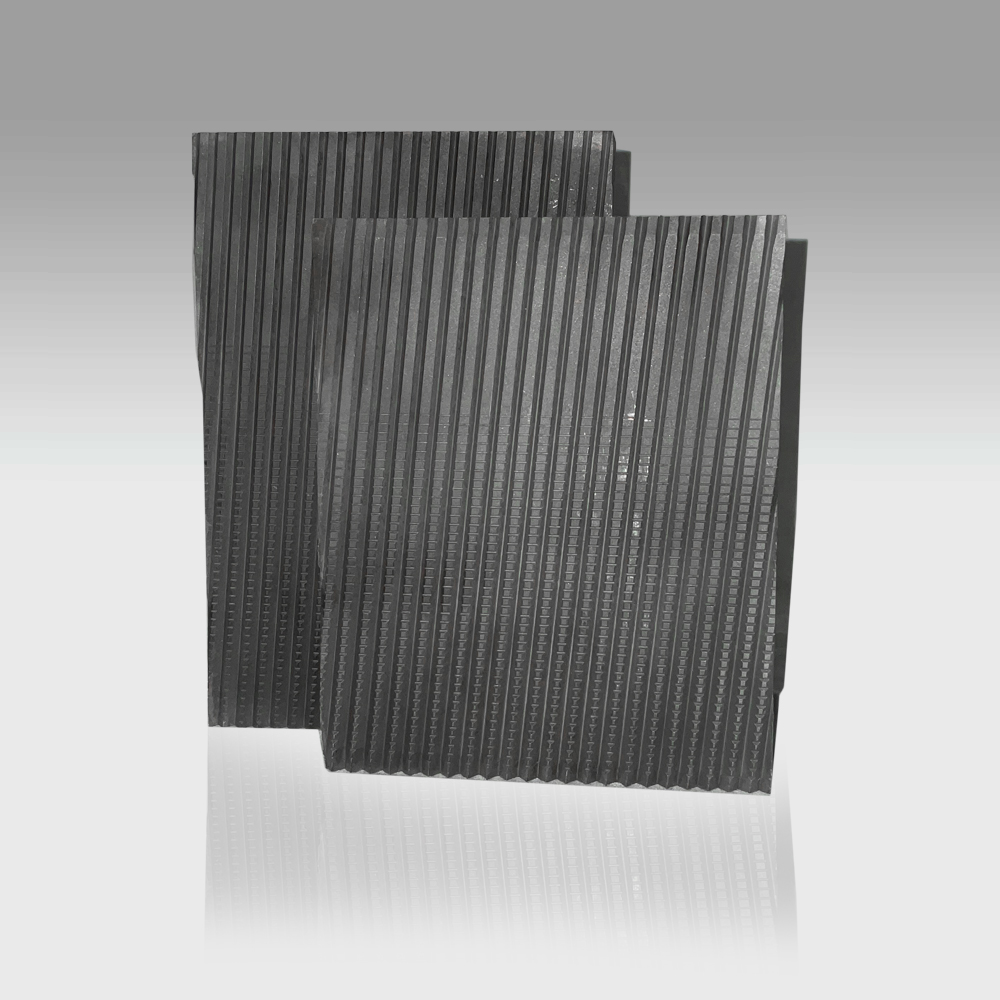

Flat thread rolling dies are crucial tools used in the manufacturing of screws and other threaded components. They play a vital role in the process of creating threads on cylindrical workpieces. Flat thread rolling dies enhances the mechanical properties of the threads and also improves their surface finish and dimensional accuracy.

Flat thread rolling dies consist of two parts: the stationary die and the moving die. The stationary die is fixed in place, while the moving die is pressed against the workpiece with significant force. As the workpiece is rotated, the moving die exerts pressure and displaces the material, creating the desired thread pattern. This process is highly efficient and capable of producing threads with tight tolerances and excellent surface quality.

Flat thread rolling dies are essential tools for the efficient and precise production of threaded components, particularly screws. Their ability to improve thread strength, consistency, and surface finish makes them a preferred choice in industries where high-quality threaded products are required.

Flat thread rolling dies come in various sizes and configurations to accommodate different screw sizes and thread pitches, making them a versatile solution for producing standardized and customized screws for various applications across industries.

OUR THREAD ROLLING DIES PROUCT RANGE

Benefits of Flat Thread Rolling Dies

Using Flat thread rolling dies for manufacturing brings many advantages, which includes:

- Enhanced Thread Strength: Thread rolling dies removes or displaces material rather than cutting it, thus resulting in better thread strength and smoother grain flow.

- Improved Surface Finish: The thread produced by these flat rolling dies are clean and precise without much imperfections. Thus additional finishing operation to smoothen the threads or surfaces are not required.

- Increased Production Efficiency: Thread rolling can be performed at high speeds, allowing for faster production rates compared to traditional threading methods.

- Extended Tool Life: Flat thread rolling dies are highly durable and resistant to wear, reducing the frequency of tool replacement and maintenance. By using these benefits, manufacturers can streamline their production processes and achieve superior quality threads consistently.

Application of Our Thread Rolling Dies

Thread rolling dies find application in various industries where threaded fasteners or components are required. Some common applications include:

Automotive Industry: Thread rolling dies are extensively used in the automotive sector for producing threaded parts such as bolts, screws, studs, and wheel studs. Thread rolling provides strong, precise threads essential for automotive assembly.

Aerospace Industry: Aerospace applications demand high precision and reliability, making thread rolling dies crucial for producing threaded components like aircraft bolts, fasteners, and hydraulic fittings.

Construction Industry: Thread rolling is employed in the construction industry for manufacturing threaded rods, anchor bolts, and structural fasteners used in buildings, bridges, and infrastructure projects.

Manufacturing Machinery: Thread rolling dies are utilized in the production of machinery and equipment, including industrial machinery, agricultural equipment, and machine tools, where threaded components are essential for assembly and functionality.

Medical Devices: Thread rolling is employed in the manufacture of medical devices such as orthopedic implants, surgical instruments, and dental implants, where precision threading is critical for proper fit and function.

Electronics Industry: Thread rolling is used for producing threaded components in electronic devices, such as connectors, terminals, and housings, ensuring secure connections and assembly integrity.

Oil and Gas Industry: Thread rolling is vital in the oil and gas sector for producing threaded components like pipeline fittings, drill pipe threads, and wellhead equipment, where reliability and strength are paramount.

Consumer Goods: Thread rolling is employed in the production of consumer goods like appliances, furniture, and sporting equipment, where threaded fasteners are used for assembly and durability.

Hardware and Fasteners: Thread rolling dies are used in the manufacturing of a wide range of hardware and fasteners, including nuts, bolts, screws, and studs, for various industrial and consumer applications.

In essence, thread rolling dies play a critical role in diverse industries where precise, high-strength threaded connections are essential for product performance, reliability, and safety.