Accusize Carbide is a leading wood screws thread rolling dies manufacturer in India. Thread rolling dies for wood screws are pivotal components in the manufacturing process of these essential fasteners. Employing a method that prioritizes precision and efficiency, these specialized dies are meticulously crafted to exacting standards. Unlike conventional cutting methods, thread rolling exerts controlled pressure on the material, yielding screws of superior strength and consistency. This process not only enhances the quality of the end product but also minimizes material wastage, underscoring its cost-effectiveness and environmental conscientiousness.

Wood screws themselves represent a cornerstone of construction and woodworking industries, valued for their versatility and reliability. The threads, impeccably formed by these dies, ensure a secure and lasting grip in various wood types, contributing to the structural integrity of countless projects. The marriage of advanced die technology with the production of wood screws not only elevates the quality of these fasteners but also augments their performance, thereby fortifying their position as indispensable components in the realm of woodworking and construction.

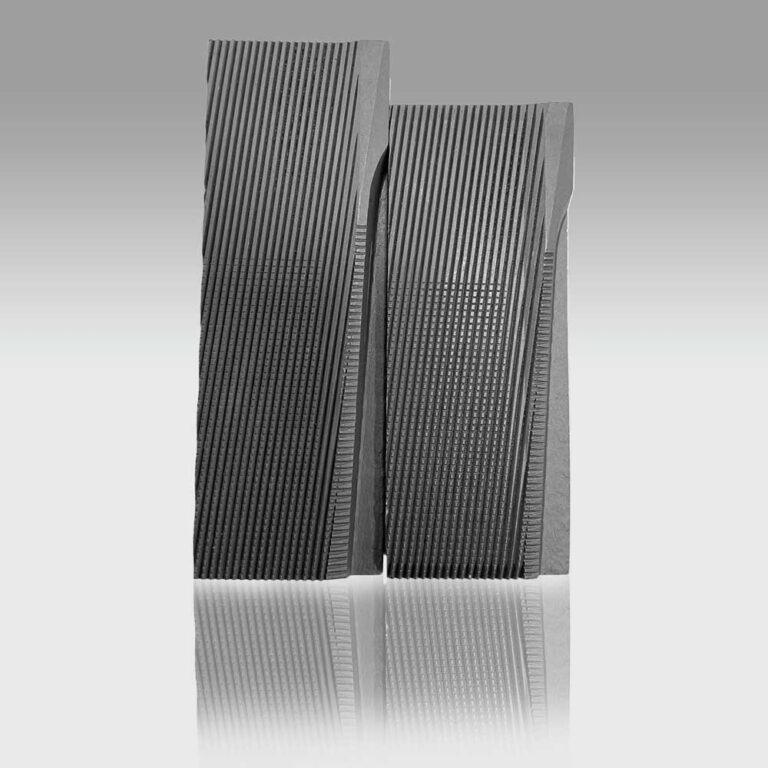

Benefits of Wood Screws Thread Rolling Dies

Wood screws rolling dies offer numerous benefits that significantly enhance the manufacturing process and the quality of wood screw products. Here are some key advantages:

Enhanced Thread Strength: Wood screws rolling dies create threads through displacement rather than removal of material, resulting in increased thread strength. This cold-working process strengthens the screw threads, making them less prone to stripping or shearing during installation.

Improved Surface Finish: Rolling dies produce threads with smooth surfaces and precise dimensions. This results in wood screws with uniform threads and minimal surface imperfections, enhancing the overall appearance and performance of the screws.

Increased Production Efficiency: Wood screws rolling dies enable high-speed, continuous production of screws with consistent thread profiles. This efficient manufacturing process reduces cycle times and increases throughput, allowing manufacturers to meet demand more effectively.

Cost Savings: By eliminating the need for secondary operations such as thread cutting or grinding, rolling dies reduce manufacturing costs associated with tooling, labor, and machine downtime. The longevity of rolling dies also leads to lower maintenance and replacement costs over time.

Versatility: Wood screws rolling dies can be customized to accommodate various screw sizes, thread pitches, and profiles. This versatility allows manufacturers to produce a wide range of wood screws tailored to specific applications and customer requirements.

Contact us for any query. We are happy to help you.

Features

- Advanced Metallurgy: Employing state-of-the-art metallurgical techniques, Wood Screw thread rolling dies are engineered from high-grade tool steel alloys. This ensures superior wear resistance, toughness, and prolonged die life, even under demanding operational conditions.

- Micro-Precision Profiling: These dies undergo a rigorous regimen of quality testing and inspection, allowing for micro-precision profiling of thread patterns. This level of accuracy guarantees uniform and flawless thread formation, even in challenging materials, contributing to superior fastening performance.

- Thermal Treatment Expertise: Each die undergoes a specialized heat treatment process, meticulously controlled to achieve optimal hardness levels. This precision heat-treating imparts exceptional durability, ensuring sustained performance over an extended operational lifespan.

- Innovative Thread Geometry: The die's thread geometry is engineered with innovative flank angles and radius, allowing for efficient chip evacuation and reduced workpiece stress. This results in superior thread integrity and surface finish, even in high-strength or brittle materials.

- Customizable Configurations: These dies offer a range of customizable options, from specialized surface finishes for specific applications to tailored thread profiles. This adaptability ensures versatility, enabling the die to address diverse fastening requirements in various industrial sectors.