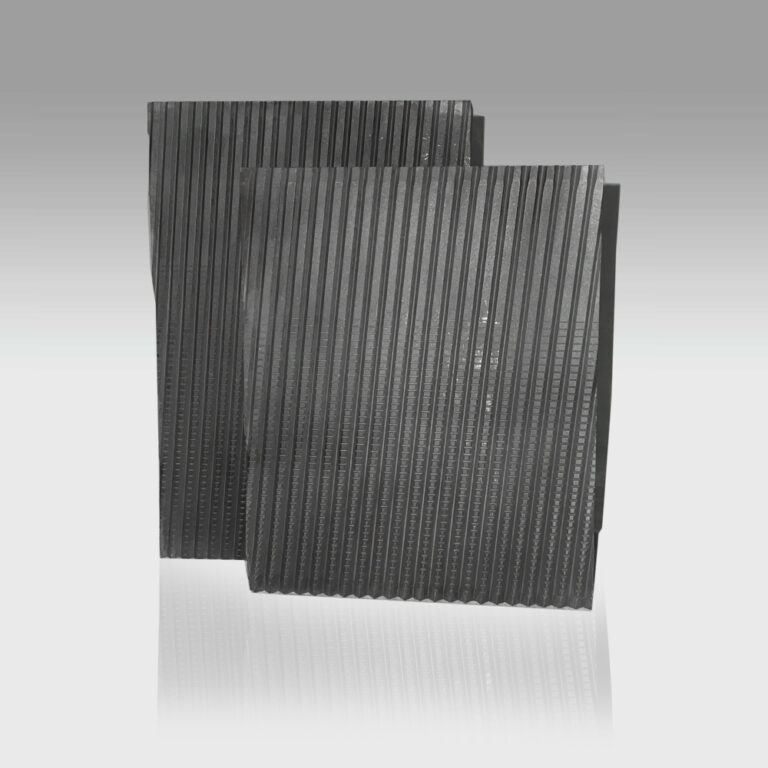

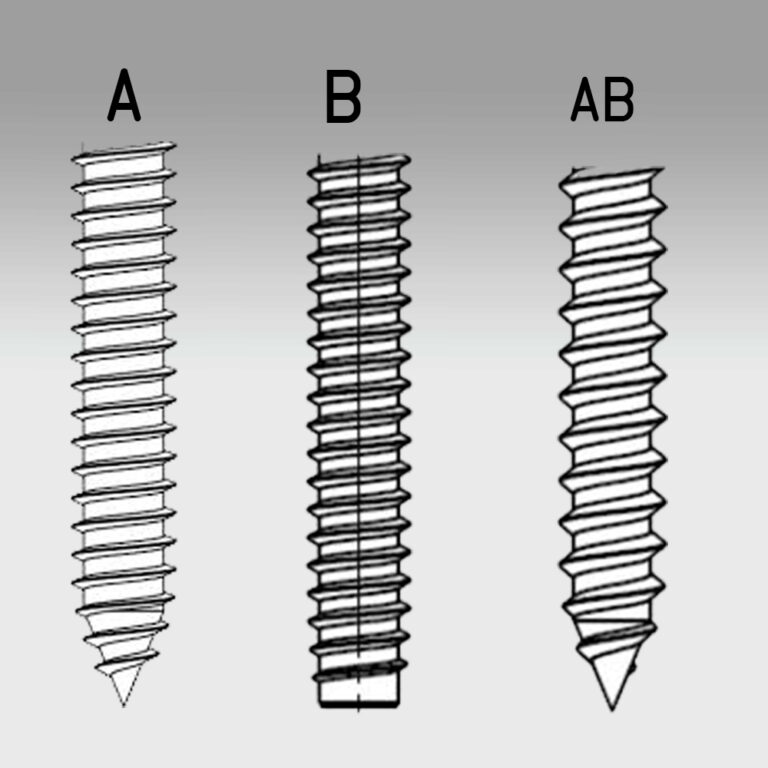

A-Type

A thread rolling die designed for A-type screws is a precision-engineered tool essential in the manufacturing of these specific fasteners. This specialized die undergoes meticulous machining to ensure utmost accuracy and durability. Its intricately crafted threads perfectly correspond to the specifications of A-type screw threads, ensuring a seamless and secure fit. Employing this die in production processes guarantees consistent and high-quality results, meeting stringent industry standards. The die’s robust construction and advanced materials enable it to withstand the rigors of high-volume production, contributing to efficiency and reliability in screw manufacturing operations. Its role in shaping threads exemplifies the critical intersection of engineering precision and industrial expertise within the realm of fastener production.

B-Type

A thread rolling die designed for B-type screws is a precision tool used in the manufacturing process to create threads on these specific screw types. This specialized die is engineered with utmost professionalism, ensuring accuracy and consistency in thread formation. It is meticulously crafted to match the unique screw point of B-type screws, allowing for seamless integration during the rolling process. The die is configured to accommodate the designated pitch and diameter specifications of B-type screws, guaranteeing a precise fit and optimal performance in the final assembly. This professional-grade tool plays a critical role in producing high-quality B-type screws, meeting industry standards and ensuring reliability in various applications.

AB-Type

A thread rolling die designed for A-type screws is a precision-engineered tool essential in the manufacturing of these specific fasteners. This specialized die undergoes meticulous machining to ensure utmost accuracy and durability. Its intricately crafted threads perfectly correspond to the specifications of A-type screw threads, ensuring a seamless and secure fit. Employing this die in production processes guarantees consistent and high-quality results, meeting stringent industry standards. The die’s robust construction and advanced materials enable it to withstand the rigors of high-volume production, contributing to efficiency and reliability in screw manufacturing operations. Its role in shaping threads exemplifies the critical intersection of engineering precision and industrial expertise within the realm of fastener production.

Contact us for any query. We are happy to help you.

Features

- Advanced Metallurgy: Employing state-of-the-art metallurgical techniques, A,B and AB Types Screw Dies thread rolling dies are engineered from high-grade tool steel alloys. This ensures superior wear resistance, toughness, and prolonged die life, even under demanding operational conditions.

- Micro-Precision Profiling: These dies undergo a rigorous regimen of quality testing and inspection, allowing for micro-precision profiling of thread patterns. This level of accuracy guarantees uniform and flawless thread formation, even in challenging materials, contributing to superior fastening performance.

- Thermal Treatment Expertise: Each die undergoes a specialized heat treatment process, meticulously controlled to achieve optimal hardness levels. This precision heat-treating imparts exceptional durability, ensuring sustained performance over an extended operational lifespan.

- Innovative Thread Geometry: The die's thread geometry is engineered with innovative flank angles and radius, allowing for efficient chip evacuation and reduced workpiece stress. This results in superior thread integrity and surface finish, even in high-strength or brittle materials.

- Customizable Configurations: These dies offer a range of customizable options, from specialized surface finishes for specific applications to tailored thread profiles. This adaptability ensures versatility, enabling the die to address diverse fastening requirements in various industrial sectors.