In the realm of manufacturing, efficiency is paramount. Every aspect of the production process, from material sourcing to assembly, needs to be finely tuned for maximum productivity. In this pursuit of optimization, one often overlooked yet crucial component is the thread rolling process. Thread rolling is a method used to form threads on cylindrical parts, offering advantages over traditional cutting methods such as increased strength, improved surface finish, and faster production rates. However, to truly unlock the potential of thread rolling, one must pay attention to the tools involved, particularly flat thread rolling dies. These precision-engineered dies play a pivotal role in enhancing the thread rolling process, leading to significant improvements in productivity and quality.

Understanding Flat Thread Rolling Dies:

Before delving into the specifics of flat thread rolling dies, it’s essential to grasp the fundamentals of thread rolling itself. Unlike thread cutting, which involves removing material to form threads, thread rolling displaces material to create the desired thread profile. This is achieved by pressing a blank part between two rotating dies, which contain the reverse image of the thread profile. As the dies apply pressure to the blank, the material is displaced to form the thread.

Thread rolling offers several advantages over cutting, including increased strength due to the cold-working of the material, improved surface finish, and higher production rates. Additionally, thread rolling can be performed on a wide range of materials, including metals like steel, aluminum, and titanium, as well as plastics.

The Role of Flat Thread Rolling Dies:

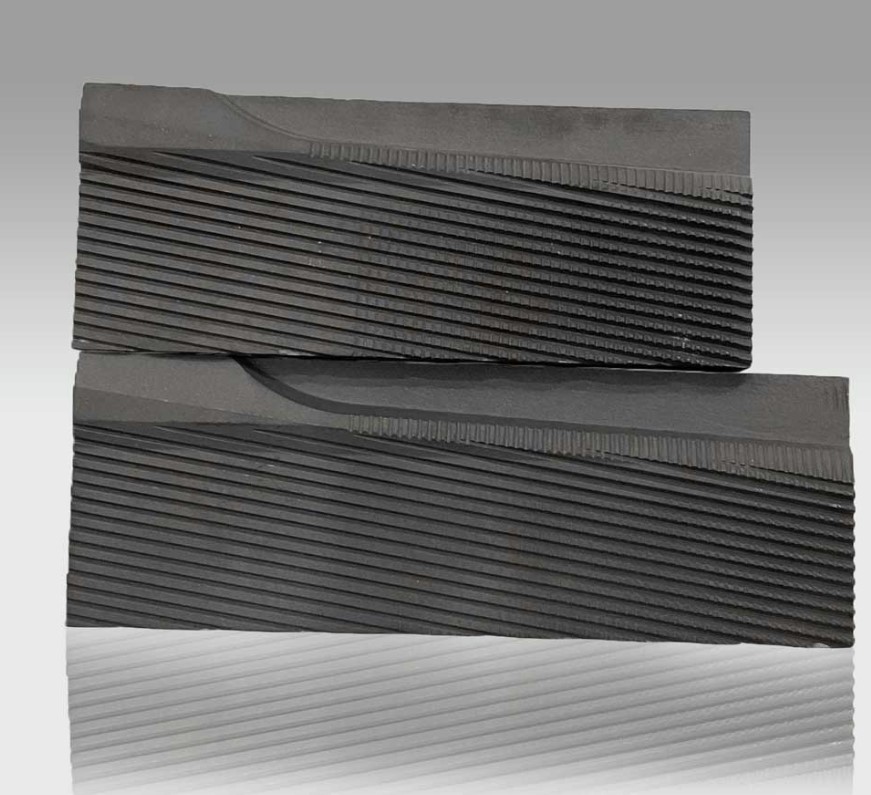

At the heart of the thread rolling process are the dies themselves. Flat thread rolling dies are specially designed tools with precise thread profiles machined onto their surfaces. These dies come in various configurations to accommodate different thread sizes, pitches, and profiles. The design of the dies directly influences the quality and efficiency of the thread rolling operation.

One of the primary functions of flat thread rolling dies is to apply the correct amount of pressure to the blank part to ensure proper thread formation. This requires careful consideration of factors such as material type, blank diameter, thread pitch, and desired thread depth. By optimizing these parameters, manufacturers can achieve consistent, high-quality threads while minimizing material waste and machine downtime.

Additionally, flat thread rolling dies play a crucial role in controlling the thread geometry and surface finish. The precise machining of the die profiles ensures that the formed threads meet the required specifications, including pitch diameter, flank angle, and thread depth. This level of accuracy is essential, especially in applications where thread integrity is critical, such as aerospace, automotive, and medical devices.

Benefits of Flat Thread Rolling Dies:

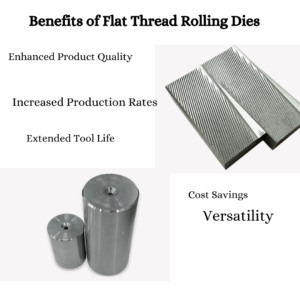

The use of flat thread rolling dies offers several key benefits that directly contribute to the optimization of the production process:

- Enhanced Product Quality: Flat thread rolling dies produce threads with superior surface finish and dimensional accuracy compared to cutting methods. This results in higher-quality parts with improved mechanical properties and better resistance to fatigue and corrosion.

- Increased Production Rates: By eliminating the need for secondary operations such as chasing or grinding, thread rolling with flat dies reduces cycle times and increases throughput. This allows manufacturers to produce more parts in less time, leading to higher overall productivity.

- Extended Tool Life: Flat thread rolling dies are made from high-quality tool steels that are hardened and precision-ground to withstand the rigors of high-volume production. This results in longer tool life and reduced maintenance costs compared to cutting tools, which can wear out quickly under heavy use.

- Cost Savings: Despite the initial investment in tooling, the long-term cost savings associated with flat thread rolling dies can be substantial. Reduced scrap rates, lower labor costs, and increased machine uptime all contribute to a more cost-effective manufacturing process.

- Versatility: Flat thread rolling dies can be easily reconfigured or replaced to accommodate different thread sizes and profiles, making them highly versatile for a wide range of applications. This flexibility allows manufacturers to adapt quickly to changing market demands and customer requirements.

Case Study: Implementing Flat Thread Rolling Dies

To illustrate the benefits of flat thread rolling dies in practice, let’s consider a hypothetical case study of a manufacturing company that specializes in producing precision threaded components for the automotive industry.

Challenge: The company is experiencing challenges with their existing thread cutting process, including high scrap rates, inconsistent thread quality, and limited production capacity. They are seeking ways to improve efficiency and reduce production costs without sacrificing quality.

Solution: After evaluating their production process, the company decides to invest in flat thread rolling dies as a solution to their challenges. They work closely with a tooling supplier to design custom dies tailored to their specific thread profiles and production requirements.

Results: Upon implementing flat thread rolling dies, the company experiences a significant improvement in their production process:

- Scrap rates are reduced by 50% due to the superior thread quality and dimensional accuracy achieved with thread rolling.

- Production capacity is increased by 30% thanks to faster cycle times and reduced machine downtime.

- Tooling costs are lowered by 20% over time due to the extended tool life of the flat thread rolling dies.

- Customer satisfaction improves as the company delivers higher-quality parts with shorter lead times and competitive pricing.

Conclusion:

Flat thread rolling dies represent a valuable tool for manufacturers looking to optimize their production processes. By leveraging the benefits of thread rolling, including increased strength, improved surface finish, and faster production rates, coupled with the precision and versatility of flat dies, manufacturers can achieve significant improvements in efficiency, quality, and cost-effectiveness. Whether it’s in automotive, aerospace, construction, or any other industry that relies on threaded components, investing in flat thread rolling dies can enhance your process and drive success in today’s competitive marketplace.