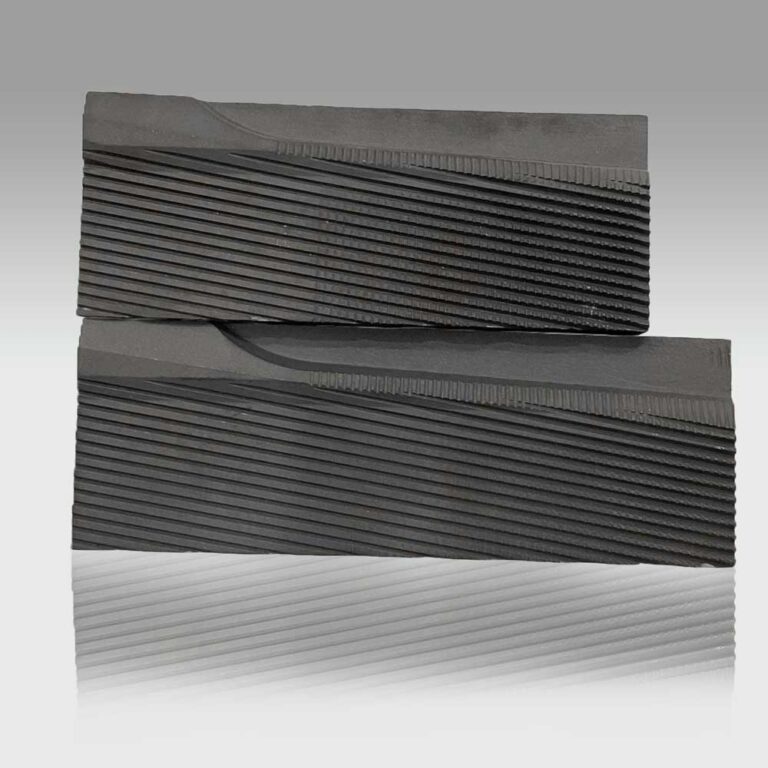

At Accusize Carbide, we are proud to say that we are the leading manufacturer of Self tapping thread dies in India. Self Tapping thread rolling dies play a pivotal role in the production of self-tapping screws, a crucial component in various industries. These dies are meticulously engineered tools designed to shape and form threads on metal rods. Crafted from high-strength materials, they undergo precise heat treatment processes to ensure durability and longevity. The die’s surface is intricately carved with the negative of the desired thread pattern, allowing it to imprint the design onto the screw’s surface during the rolling process.

The rolling process itself involves pressing the die against the metal rod, which causes the material to flow and form threads. This method not only produces threads of exceptional accuracy but also imparts enhanced strength to the screws. These dies come in a range of sizes to accommodate different screw dimensions, and their design can be customized to suit specific threading requirements.

Self Tapping thread rolling dies are indispensable tools in the manufacturing process, contributing to the production of high-quality, reliable self-tapping screws that find extensive use in construction, automotive, and various other industries worldwide

Contact us for any query. We are happy to help you.

Features

- Advanced Metallurgy: Employing state-of-the-art metallurgical techniques, Self Tapping Screw dies are engineered from high-grade tool steel alloys. This ensures superior wear resistance, toughness, and prolonged die life, even under demanding operational conditions.

- Micro-Precision Profiling: These dies undergo a rigorous regimen of quality testing and inspection, allowing for micro-precision profiling of thread patterns. This level of accuracy guarantees uniform and flawless thread formation, even in challenging materials, contributing to superior fastening performance.

- Thermal Treatment Expertise: Each die undergoes a specialized heat treatment process, meticulously controlled to achieve optimal hardness levels. This precision heat-treating imparts exceptional durability, ensuring sustained performance over an extended operational lifespan.

- Innovative Thread Geometry: The die's thread geometry is engineered with innovative flank angles and radius, allowing for efficient chip evacuation and reduced workpiece stress. This results in superior thread integrity and surface finish, even in high-strength or brittle materials.

- Customizable Configurations: These dies offer a range of customizable options, from specialized surface finishes for specific applications to tailored thread profiles. This adaptability ensures versatility, enabling the die to address diverse fastening requirements in various industrial sectors.